Macrodyne is a trusted mining press manufacturer, delivering press machines for mining operations that are built for continuous, high-load performance.

Our heavy-duty mining presses are engineered for the demands of material processing, equipment fabrication, and component forming in the mining sector, providing consistent force, precise control and long service life in the most challenging environments.

As experienced mining press manufacturers, we design and build heavy-duty mining presses tailored to the needs of the mining industry. From material processing to equipment fabrication, our press solutions are engineered for maximum durability, precision and performance in demanding mining environments.

(including Ram Extrusion) – Form continuous, high-strength profiles with precise dimensions for demanding structural and mechanical uses.

Apply controlled force to straighten or shape oversized workpieces while maintaining structural integrity.

Compact refractory materials into dense, uniform shapes capable of withstanding high heat and harsh environments.

Produce high-density parts from powdered metals or ceramics, ensuring consistent quality and performance.

Provide fast, repeatable sheet metal forming for a variety of components, optimizing throughput and precision.

Restore critical alignment to shafts, beams, and other structural elements for optimal performance and longevity.

With Macrodyne’s high-force hydraulic presses, you can manufacture critical aircraft, defense, and space components with unmatched accuracy and repeatability. From fuselage panels and jet engine casings to landing gear and spacecraft structures, our advanced forming technologies ensure every part is built to perform.

Our heavy-duty mining presses manufacture critical components for mining operations, from structural frames to high-wear parts, with the precision and durability the industry demands.

Frames & Support Structures – High-strength forged or formed frames for crushers, conveyors, and drilling rigs.

Beams & Bracing Members – Precision-formed structural supports for underground and surface mining equipment.

Protective Enclosures – Stamped or fabricated housings for motors, gearboxes, and operator cabins.

Gears & Pinions – Forged or cold-formed gears for crushers, mills, and heavy-duty drives.

Drive Shafts & Couplings – Precision-formed components for power transfer in mining vehicles and equipment.

Bearing Housings – Forged or machined housings for critical rotating assemblies.

Chute & Hopper Liners – Stamped or formed wear plates for ore handling and material transfer.

Rollers & Pulley Shells – Formed components for conveyor systems in bulk material handling.

Crusher Wear Parts – Forged or stamped impact plates, mantles, and jaw dies for crushing equipment.

Cylinder Tubes & End Caps – Deep-drawn or forged components for hydraulic systems in loaders, shovels, and drills.

Valve Bodies & Pump Housings – Precision-formed parts for fluid control systems in mining machinery.

Seal Rings & Gaskets – Compression-molded sealing components for high-pressure applications.

Bucket Lips & Cutting Edges – Forged or stamped edges for shovels, loaders, and excavators.

Track Shoes & Undercarriage Links – Cold-formed and forged parts built for extreme abrasion resistance.

Reinforcement Plates & Guards – Stamped plates to protect high-wear areas on mining machines.

Drill Rod & Bit Components – Forged and machined parts for rock drilling applications.

Blade & Ripper Components – Heavy-formed steel parts for dozers and graders in mine sites.

Couplers & Connection Systems – Forged and stamped hardware for quick attachment changes.

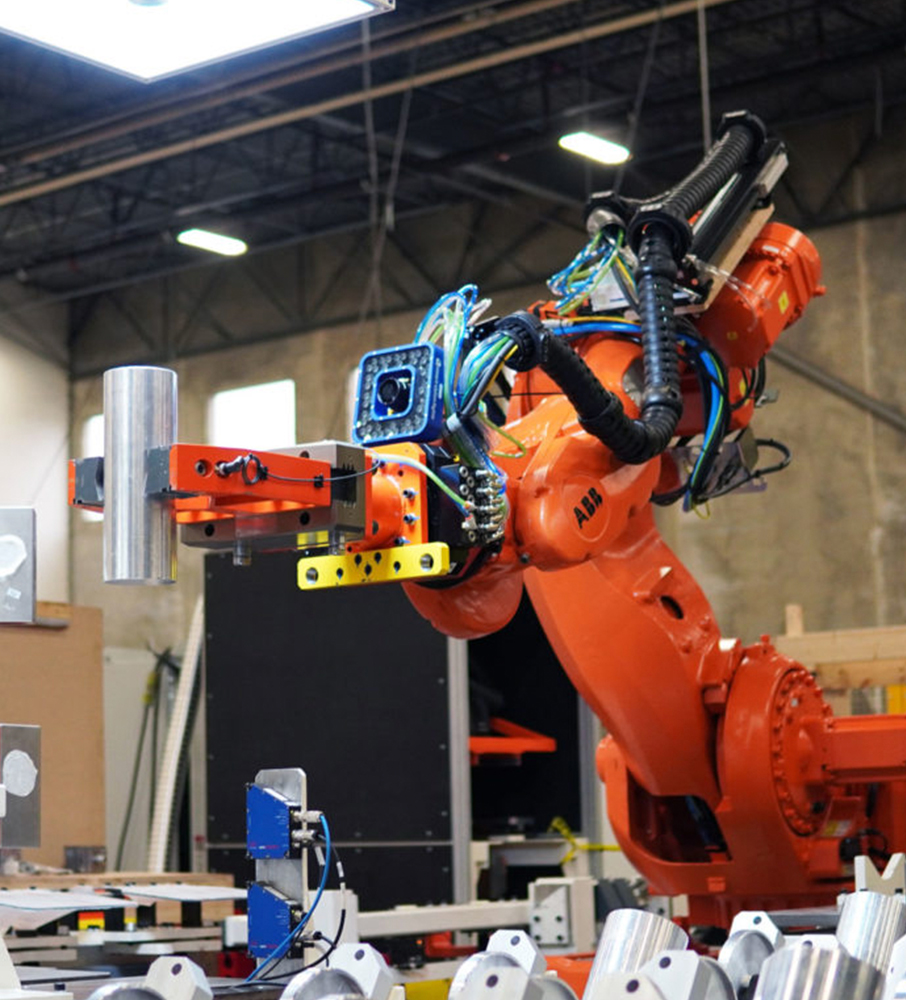

Macrodyne’s automation solutions are built to handle the heavy loads, abrasive materials, and demanding conditions of the mining industry. We engineer fully integrated systems for press machines used in mining operations, combining robotics, material handling, and process control into a seamless production flow.

From automating a single heavy-duty mining press to optimizing an entire component manufacturing line, our mining press automation solutions reduce downtime, increase throughput, and maintain consistent quality in the most challenging environments.

Let Macrodyne deliver the precision and performance your manufacturing demands with industry-leading hydraulic presses and servo presses.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.