Refractory Brick Presses

Refractory Brick Press Machines

Advanced density, uniformity and dimensional precision.

Macrodyne refractory brick presses are purpose-built for producing high-quality refractory bricks, and they can also be adapted for other powder compaction applications.

These hydraulic or servo single- or multi-action compaction presses can be combined with our advanced control systems to provide a superior solution for all your production requirements.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Refractory Brick Press Machines

Advanced density, uniformity and dimensional precision.

Macrodyne refractory brick presses are purpose-built for producing high-quality refractory bricks, and they can also be adapted for other powder compaction applications.

These hydraulic or servo single- or multi-action compaction presses can be combined with our advanced control systems to provide a superior solution for all your production requirements.

View Past Projects

What is a Refractory Brick Press?

A refractory brick press is a specialized compaction press designed to create the heat-resistant bricks used to line furnaces and kilns. These specialty bricks are made from a variety of complex composite heat-resistant materials and are compacted under extremely high pressure with a refractory brick press into the designed shape.

Custom Hydraulic Brick Presses and Servo Brick Presses

Your hydraulic or servo refractory brick press can be engineered to meet your specific pressure and full-depth requirements. Choose from a 4-column or monolithic frame design, each optimized to your production needs

Automate Your Line with Macrodyne

Each brick press can be developed as a standalone piece of equipment or integrated into a sophisticated automation system complete with feeders, material handling equipment and more. We’ll design the right system for your production goals and budget, whether that means a standalone press or a fully automated line.

Options include:

- Charger box with blender assembly – ensure even material distribution

- Part load and unload devices – improve throughput and reduce manual handling

- Mixers – guarantee uniform blends for consistent quality

- Robots – automate handling for efficiency and safety

- Ejectors – enable clean and reliable part release

- Automated weigh feeders – maintain accuracy in material input

- Heated platens – support specialized curing requirements

- High-speed controllers – enhance process precision

- Single- or multi-action presses – match your production complexity

- 4-column or monolithic frames – select the right structure for your application

- CBH ring adapter – increase flexibility in tooling setups

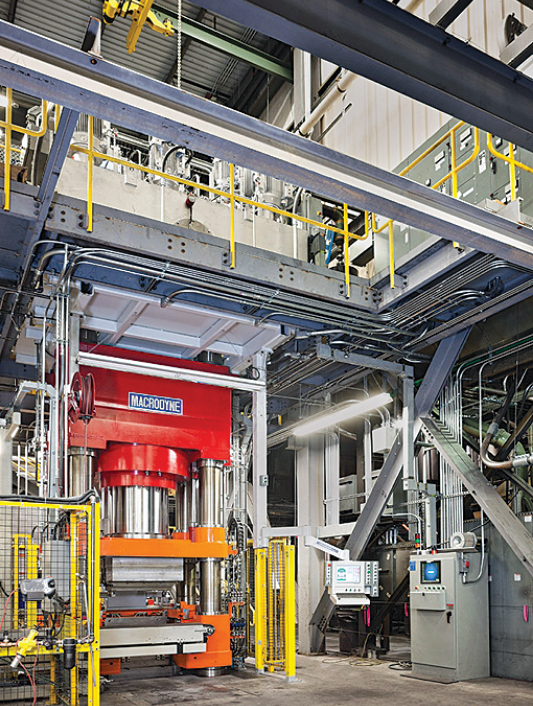

2250/130 ton refractory brick press

Macrodyne Compaction Presses for Pressed Brick and More

Macrodyne compaction presses work with powdered compounds for a variety of applications, including:

- Refractory brick (firebrick) – heat-resistant linings for furnaces and kilns

- Metal powder compaction – automotive components with superior density

- Ceramic compaction – tableware and sanitary ware with precise finishes

- Technical and bio ceramics – advanced ceramics for specialized uses

- Magnetic materials – automotive, appliance and medical applications

- Tantalum compaction – components for pharmaceutical and chemical processing

- PTFE – solutions for appliances, oil and gas, and chemical industries

Contact us and ask how we can develop a compaction press for your unique application.

Think Big with Macrodyne

Learn more about our industrial press design and automation solutions.