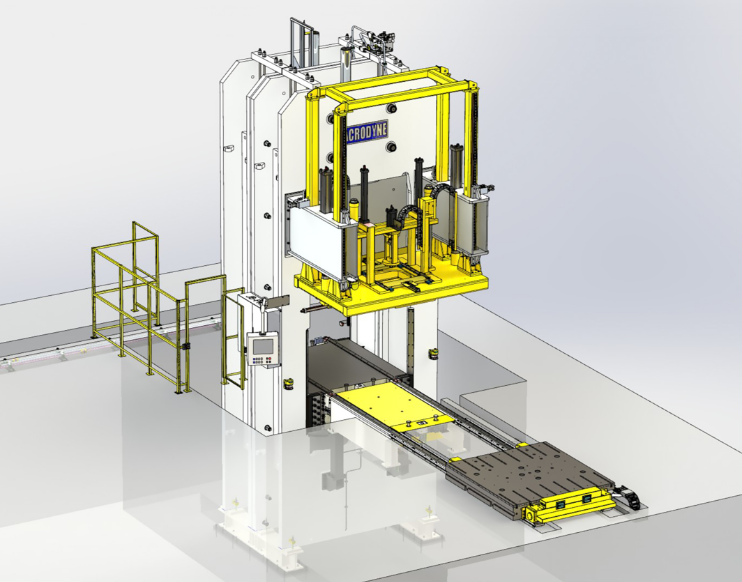

Rubber Molding Presses

Industrial Rubber Molding Presses

A cost-effective tooling solution offering market-leading precision.

Your Macrodyne rubber molding press delivers the repeatable precision you need to mold custom rubber products with confidence.

Our custom-engineered presses serve the aerospace, automotive and industrial equipment manufacturing industries with the customized pressure and temperature distribution required to produce a variety of rubberized parts with exceptional accuracy.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Industrial Rubber Molding Presses

A cost-effective tooling solution offering market-leading precision.

Your Macrodyne rubber molding press delivers the repeatable precision you need to mold custom rubber products with confidence.

Our custom-engineered presses serve the aerospace, automotive and industrial equipment manufacturing industries with the customized pressure and temperature distribution required to produce a variety of rubberized parts with exceptional accuracy.

View Past Projects

Macrodyne Custom Hydraulic Presses and Servo Presses

Your press can be built in a monolithic or multi-frame style, with either an up-stroking or down-stroking configuration — tailored to your production needs.

Your preferred rubber molding press can be optimized for load compression molding or transfer molding, and produce large rubber components or mold/bond large rubber and metal assemblies. Cycle times can be configured to your specific material requirements.

Other options include:

- Steam, thermal oil, or electrically heated platens – consistent heating for quality molding

- Gas, propane, or electrically fired heating systems – flexible energy options for your facility

- Platen cooling systems – faster cycle times and improved part quality

- Vacuum enclosures and systems – reduce defects and improve consistency

- Insulated heat enclosures – conserve energy and stabilize temperature

- Platen cleaners – reduce downtime and keep surfaces production-ready

- High-speed data acquisition systems – monitor and optimize performance in real time

Produce Multiple Molds in a Single Press with a Macrodyne Rubber Molding Machine

Run multiple molds at once with your Macrodyne press, producing several parts in a single cycle. This saves time and reduces the number of presses you need for longer cure-time parts. This feature is especially helpful when parts take a longer time to cure, meaning you need fewer presses to meet your production goals.

Automate Your Line with Macrodyne

Increase production, quality and safety in your manufacturing facility. Consult with us about our range of rubber molding press line automation options, including:

- Heating and cooling systems – maintain optimal processing conditions

- Press loading and unloading systems – reduce manual handling and increase throughput

- Specialized material handling and conveying systems – streamline your workflow

- Mold fill systems – ensure accurate and consistent part formation

- Process plate transfer systems – simplify handling between presses

- And more – fully customized to your operation

Think Big with Macrodyne

Learn more about our industrial press design and automation solutions.