Horizontal Bulldozer Presses

Industrial Horizontal Bulldozer Hydraulic and Servo Presses

Engineered for precision, force control and greater workflow efficiency.

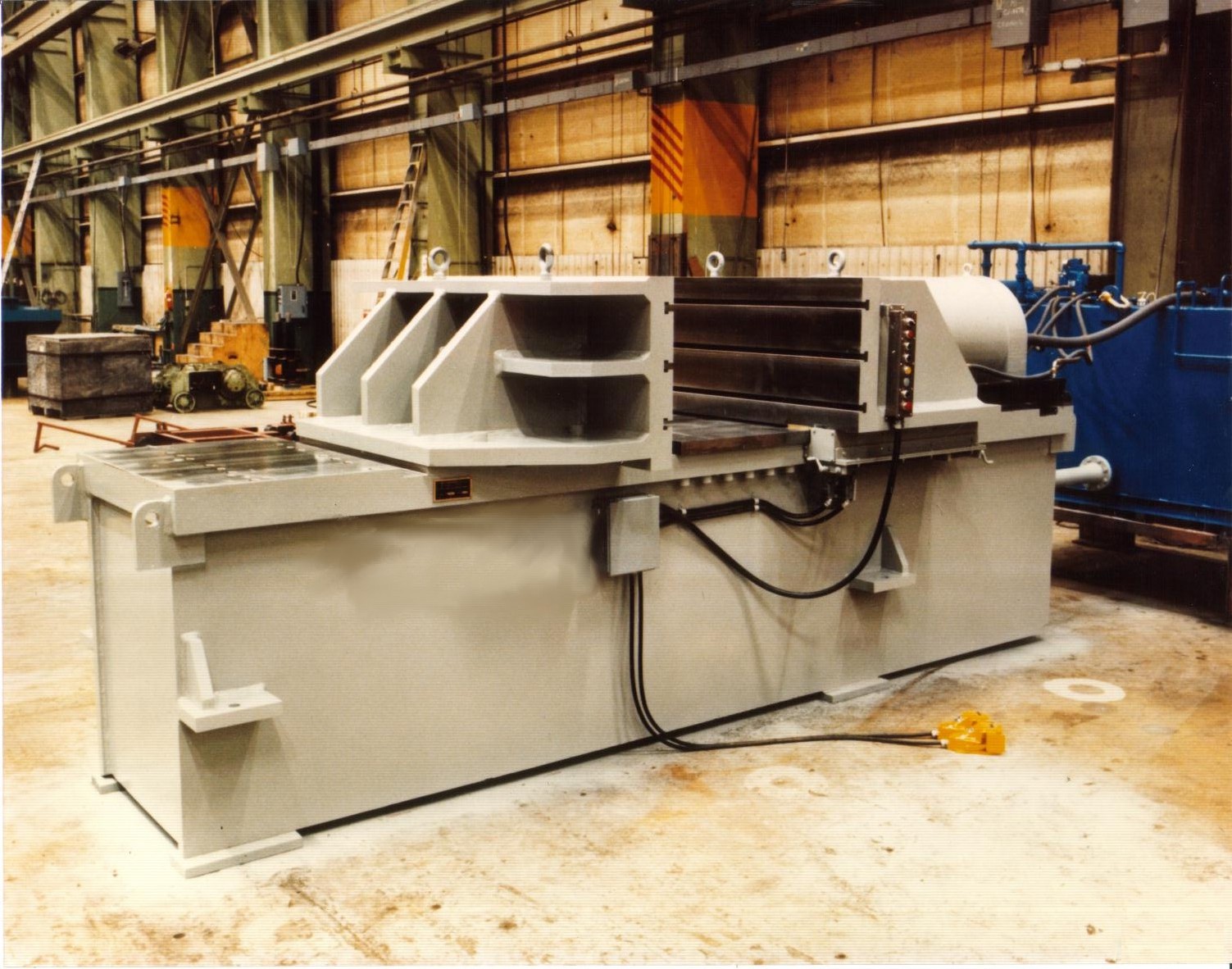

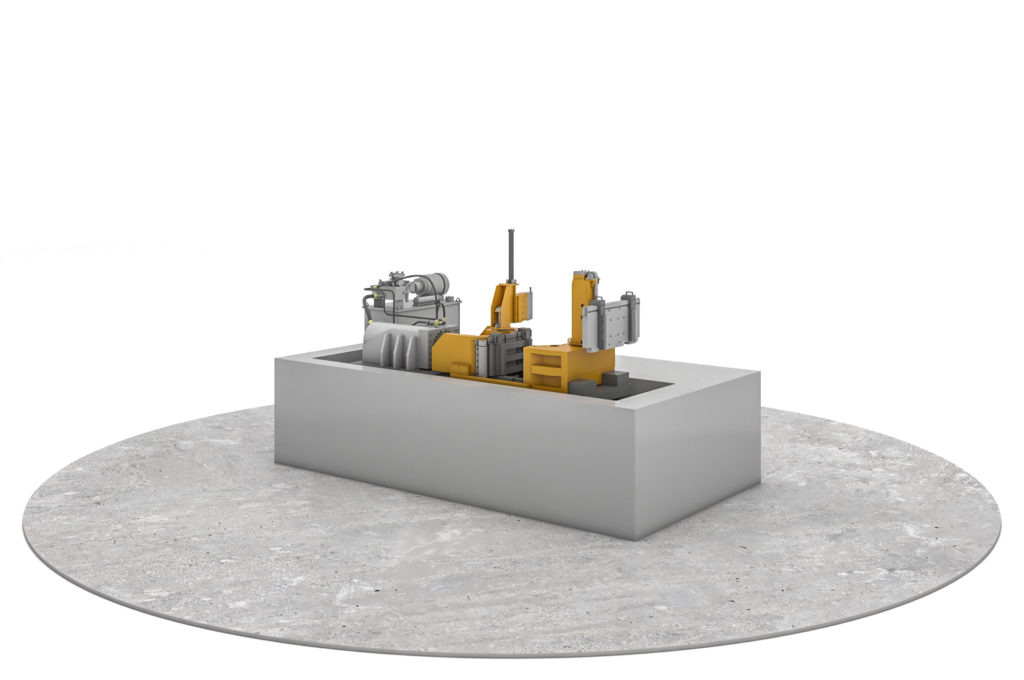

Macrodyne’s horizontal bulldozer presses are designed to bend, form and straighten sheet metal into a variety of configurations. These custom-engineered presses can be developed in either a gap- or column-style frame configuration, optimized to your unique application.

All presses are developed through finite element analysis (FEA) to ensure the deflection and stresses generated during pressing are optimized to your finished product.

Unlike vertical presses, our horizontal bulldozer presses feature a deeper throat depth to handle larger parts, improve material flow, and offer greater mold design flexibility.

Our horizontal bulldozer presses feature a gib-guiding system to offer enhanced parallel slide motion and eccentric load capabilities. These presses come with fully integrated controls for precise, automatic control of stroke and tonnage.

Custom Horizontal Bulldozer Presses

Macrodyne is a global leader in custom hydraulic and servo presses. We design horizontal bulldozer presses tailored to your application and budget.

A variety of options are available, including:

- Capacities up to 2,000 tons

- Multi-tool capability for diverse applications

- Faster speeds and longer strokes available

- Self-contained hydraulic power unit

- Advanced press controls for reliability and consistency

Automation Solutions for Horizontal Press Machines

Automate your line with Macrodyne. As automation specialists, we can complement your horizontal press machine with a wide range of automation features, including:

- Loading and unloading equipment – improve throughput and reduce manual handling

- Robots – automate part transfer with precision

- Decoilers and destackers – streamline sheet feeding and preparation

- Automated conveyors/belts – ensure smooth part flow through the line

- Vacuums, scrap removal systems, and disposal chutes – maintain a clean, safe workspace

- Hydraulic ejection cylinders – enable faster part removal and higher cycle rates

- Vibro-isolator packages – minimize vibration for better accuracy and longevity

- Safety packages (lock pin, light curtains, safety gates) – protect operators and equipment

- Die carts and quick die change package – reduce downtime during changeovers

Think Big with Macrodyne

Learn more about our industrial press design and automation solutions.