Superplastic Forming Presses

Gas Oscillation Enhanced Superplastic Forming Presses

The next generation in superplastic forming.

Macrodyne’s revolutionary Gas Oscillation Superplastic Forming (GO-SPF) technology is a disruptive advancement in the SPF process that pushes the boundaries of conventional superplastic forming, allowing for dramatically more geometrically complex parts to be formed with higher quality and at lower costs.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Gas Oscillation Enhanced Superplastic Forming Presses

The next generation in superplastic forming.

Macrodyne’s revolutionary Gas Oscillation Superplastic Forming (GO-SPF) technology is a disruptive advancement in the SPF process that pushes the boundaries of conventional superplastic forming, allowing for dramatically more geometrically complex parts to be formed with higher quality and at lower costs.

View Past Projects

Advantages of Macrodyne’s Proprietary Superplastic Forming Technology

Our patented superplastic forming technology transforms the decades-old conventional SPF process into the next generation of press manufacturing.

- Improved manufacturing speeds (200% – 1,000%)

- Increased elongation-strain with more uniform thickness

- Improved manufactured part quality

- Ability to manufacture at higher strain rates

- Ability to manufacture thinner parts

- Ability to manufacture more complex-shaped parts

- Ability to manufacture parts previously considered “un-manufacturable”

- Increased light-weighting opportunities

GO-SPF Will Revolutionize the Way You Work

Industries

- Automotive: body panels, doors, fenders, lift gates, roofs, floor panels

- Aerospace: panels for aircraft engines and others

- Defense

- Medical

- Architectural

- Marine

Materials

Our unique gas oscillation forming system has no moving parts that can fail in a high-temperature environment, significantly improving the formability of lightweight metallic sheets, such as

- Aluminum

- Magnesium

- Titanium

- Other alloys

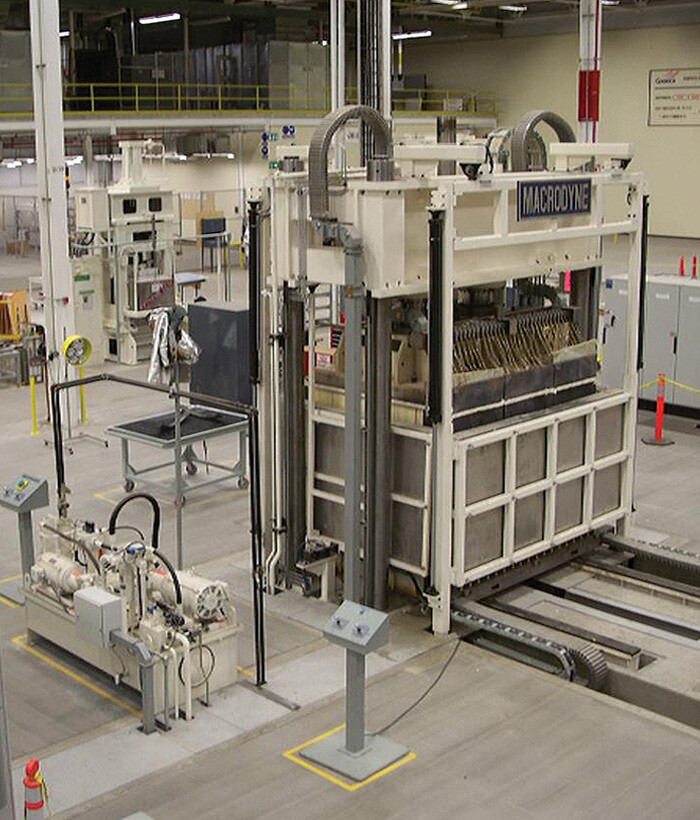

Macrodyne Superplastic Forming Press

Our GO-SPF presses feature the same high level of quality, attention to detail and engineering excellence you would expect with any Macrodyne hydraulic or servo press.

Accurate and repeatable argon gas pressures and multi-zone temperature controls are critical elements in the GO-SPF process. These variables are managed through our easy-to-use press control system.

Macrodyne Hydraulic and Servo Superplastic Forming Presses

Macrodyne superplastic forming presses include a variety of standard features, such as:

- Precise and uniform multi-zone temperature control

- Specialized plunger guide arrangements

- Precision gas management systems

- High-speed data acquisition systems

- Highly efficient heat shields and ceramic insulation

- Heated platens

- Cooling platens

- Rolling bolsters

- Remote diagnostics

Each press can be custom-designed in a myriad of ways for any application.

Customized mechanisms can be geared to each application according to the:

- Forming part geometry

- Type of metallic alloy

- Tool design

Systems are custom-engineered to generate controlled waves of gas pressure inside the forming tool, gently pushing and releasing the material repeatedly. This push-and-release action helps the material stretch more easily and reduces the stress built up during the forming process, resulting in better material flow and stronger finished parts.