Compaction Presses

Industrial Powder Compaction Hydraulic and Servo Presses

Ensure consistent part quality with precise density control and repeatable compaction.

Industrial compaction presses apply extremely high force over a minimal area to create solid parts from powder compounds with precision and repeatability.

Our presses feature advanced control systems and are available in single-action or multi-action designs for a variety of applications.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Industrial Powder Compaction Hydraulic and Servo Presses

Ensure consistent part quality with precise density control and repeatable compaction.

Industrial compaction presses apply extremely high force over a minimal area to create solid parts from powder compounds with precision and repeatability.

Our presses feature advanced control systems and are available in single-action or multi-action designs for a variety of applications.

View Past Projects

What is Compaction?

Compaction presses powdered raw materials into solid parts under extremely high pressure. The process offers near-zero waste, high throughput, design flexibility and excellent dimensional control.

Macrodyne Compaction Press Solutions

Macrodyne’s powder compacting presses are used for many innovative applications, including:

- Refractory brick – durable fire-resistant materials for kilns and furnaces

- Metal powder components – strong, lightweight automotive parts

- Ceramic compaction (table/sanitary ware) – consistent finish and durability

- Technical and bio ceramics – high precision for specialized industries

- Magnetic materials – reliable performance in automotive, appliances, and medical uses

- Tantalum compaction – advanced applications in pharmaceuticals and chemical processing

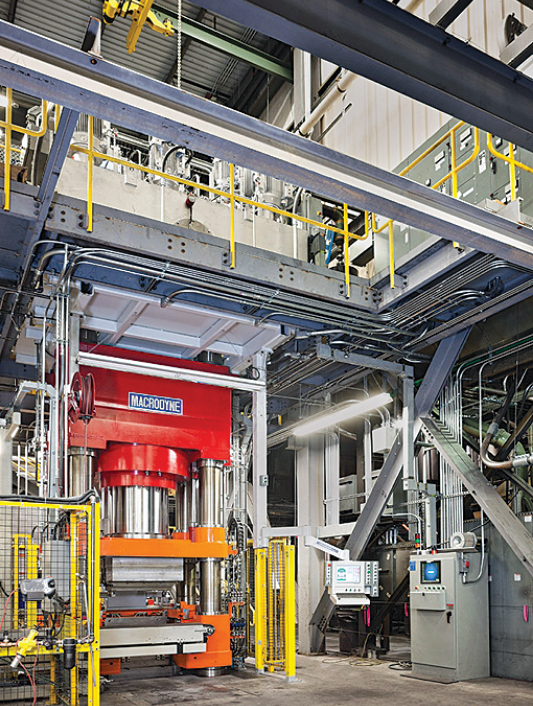

2250/130 ton compaction press for refractory brick

Custom Hydraulic and Servo Compaction Presses

Your compaction press is built to order, designed around your material, fill depth and pressure requirements.

Available in 4-column or monolithic frame styles, each machine is engineered to deliver reliability, precision and long-term performance.

Automate Your Line with Macrodyne

Increase production, quality and safety in your manufacturing facility. Consult with us about our range of compaction press line automation options, including:

- Chargers – ensure accurate powder filling

- Part load/unload devices – speed up handling and reduce downtime

- Mixers – maintain consistency in powder blends

- Robots – automate repetitive handling tasks

- Ejectors – provide safe, efficient part removal

- Weigh feeders – improve accuracy and reduce waste

Think Big with Macrodyne

Learn more about our industrial press design and automation solutions.