Rail and transit manufacturing comes with tough challenges — forming high-strength materials, handling oversized components, and ensuring precision at every step. To meet these demands, manufacturers rely on hydraulic presses for the rail industry that deliver the tonnage, process control, and automation needed for high-precision production.

Macrodyne’s hydraulic presses for the transportation industry are engineered for efficiency, helping manufacturers streamline operations, improve repeatability, and reduce downtime.

Whether you’re shaping structural panels, forming critical undercarriage components, or forging high-performance wheels, our custom presses for the rail industry provide the reliability and strength to keep production moving.

When production demands efficiency, repeatability, and reliability, Macrodyne’s high-performance press solutions deliver. Our hydraulic presses for the rail industry are designed for long-term durability and seamless automation, ensuring precision in every forming operation.

With a proven track record in hydraulic presses for the transportation industry, we provide manufacturers with a low-risk solution that maximizes output while minimizing downtime. Whether standard or custom-engineered, our custom presses for the rail industry are built to handle the toughest manufacturing challenges with superior performance and consistency.

Macrodyne’s forging presses are designed to produce a variety of forged products, including gears, flanges, bearings, wheels, shafts, axles, and other heavy industrial components. As part of our advanced forging systems for the railway industry, these presses deliver the precision and force required to manufacture durable, high-performance rail components.

The repeatable precision of our deep draw presses ensures optimal process control for high-strength forming applications. Engineered for reliability, they minimize material inconsistencies and deliver superior efficiency in demanding production environments.

Our cold forging presses feature deep slides with high width-to-height ratios, designed to withstand extreme forming forces with unmatched accuracy. Their robust construction and advanced controls ensure long-term durability and process stability.

Macrodyne’s heavy-duty heated platen presses provide uniform pressure and temperature distribution, critical for processing advanced materials. Built for reliability, they ensure consistent, high-quality output in high-volume production.

As a premier supplier of compression molding presses, we deliver unmatched precision and repeatability for forming high-performance materials. Our presses are built for efficiency, reducing cycle times and maximizing production uptime.

Our coining presses feature advanced control systems that ensure precise, repeatable force application, critical for high-accuracy forming operations. Engineered for high-volume production, they optimize cycle times while maintaining exceptional quality.

Macrodyne’s stamping presses combine high tonnage with precision control, delivering superior forming accuracy and process efficiency. With rugged construction and intelligent automation, they ensure long-term reliability in heavy-duty applications.

Manufactured by Macrodyne-DUNKES, our straightening presses provide the precision and force required to correct material deviations with exceptional accuracy. Engineered for demanding applications, they improve efficiency and reduce rework in high-volume operations.

With Macrodyne’s high-force hydraulic presses, you can manufacture critical aircraft, defense, and space components with unmatched accuracy and repeatability. From fuselage panels and jet engine casings to landing gear and spacecraft structures, our advanced forming technologies ensure every part is built to perform.

Railcar Side Panels – Large aluminum or steel panels forming the outer shell of railcars.

Roof & Floor Panels – Structural sections ensuring strength and durability for train and transit vehicles.

Chassis Frames – Rigid structures providing support for buses, trams, and railway cars.

Underframes & Bogie Frames – Load-bearing components housing axles and wheel assemblies.

End Walls & Bulkheads – Reinforced barriers for impact protection and structural integrity.

Locomotive & Railcar Wheels – Forged and formed wheels for freight and passenger rail applications.

Axles & Housings – High-strength, precision-formed components for wheel assemblies.

Brake Discs & Rotors – Heat-resistant, stamped or forged components for braking systems.

Doors & Door Frames – Stamped or deep-drawn structures for train and bus entryways.

Seating Components – Molded or formed frames for durable passenger seating.

Dashboards & Control Panels – Precision-formed panels for operator and passenger interfaces.

Energy Absorption Components – Crash-resistant elements for impact safety in railcars.

Suspension & Shock Absorber Housings – Cold-forged or stamped components for ride stability.

Couplers & Buffers – Forged parts that connect train cars and absorb impact forces.

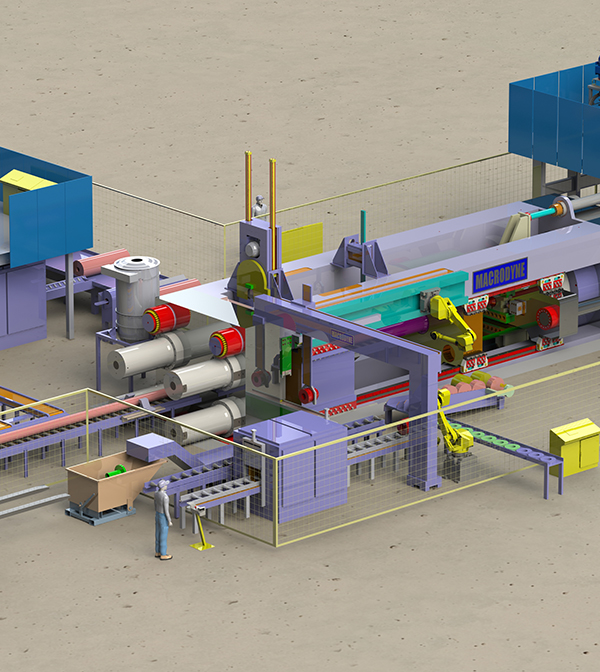

Manufacturing for the rail and transportation industry demands more than just precision. It requires efficiency, consistency, and reliability at scale. Macrodyne’s automation division delivers tailored, machine-designed solutions that go beyond basic conveyors and robots to provide fully integrated, end-to-end automation.

As a Fortune 500-proven partner, we offer low-risk, high-performance automation built for uptime, reliability, and long-term success. Whether you’re upgrading a single press or automating your entire production line, Macrodyne delivers solutions that keep you ahead.

Let Macrodyne deliver the precision and performance your manufacturing demands with industry-leading Servo Presses and Hydraulic Presses for the rail industry.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.