Medical manufacturing demands precision, consistency, and absolute reliability — all within highly controlled environments. Many processes take place in clean rooms, where even the smallest contamination can compromise product integrity. To achieve this, manufacturers turn to custom presses for medical manufacturing that deliver the force, accuracy, and automation required for high-precision production in these critical settings.

Macrodyne’s medical hydraulic presses are engineered for efficiency, helping manufacturers streamline operations, improve repeatability and ensure compliance with strict regulatory requirements, all while maintaining the clean room standards necessary for medical device production.

Choosing the right press is critical in medical hydraulic press applications, where precision, repeatability, and compliance with strict industry standards are non-negotiable. From shaping advanced materials to forming high-performance medical components, each process demands specialized equipment.

At Macrodyne, we design custom presses for medical manufacturing that deliver the force, accuracy, and control required for everything from implant production to diagnostic device assembly.

Engineered for precision and repeatability, our hydraulic deep draw presses ensure optimal process control for forming complex medical components from a variety of materials.

Designed for the production of composite and polymer-based parts, our hydraulic compression molding presses provide consistent force and accuracy for medical manufacturing applications.

Built for high- and low-pressure hydroforming, these presses allow for the shaping of intricate medical components with uniform wall thickness and minimal material stress.

Featuring an enclosed vacuum chamber, these presses eliminate air pockets, ensuring consistent molding and bonding for high-purity medical applications.

Combining hydraulic force with servo precision, these presses offer superior control, fast cycle times, and repeatable accuracy for specialized medical manufacturing.

Designed for precision shaping without heat, our cold forming presses deliver high-strength medical components with minimal material waste.

With Macrodyne’s high-force hydraulic presses, you can manufacture critical aircraft, defense, and space components with unmatched accuracy and repeatability. From fuselage panels and jet engine casings to landing gear and spacecraft structures, our advanced forming technologies ensure every part is built to perform.

From surgical instruments to advanced prosthetics, medical hydraulic presses play a critical role in producing high-precision components that meet strict industry standards. Whether forming intricate implants, shaping device enclosures, or molding pharmaceutical packaging, manufacturers rely on custom presses for medical manufacturing to ensure consistency, reliability and compliance.

Orthopedic Implants – Precision-formed components for joint replacements, bone plates, and fixation devices.

Dental & Cranial Implants – High-strength metal and composite structures for surgical implantation.

Surgical Instruments – Deep-drawn, stamped, or forged tools used in operating rooms and medical procedures.

Diagnostic Equipment Casings – Formed metal and composite enclosures for imaging, monitoring, and laboratory devices.

Sterile Packaging & Trays – Compression-molded or laminated structures for secure medical packaging.

Wearable Medical Device Components – Lightweight, molded, and bonded parts for patient monitoring systems.

Tablet & Capsule Press Components – Precision-formed parts used in pharmaceutical production and processing.

Lab Testing & Analysis Equipment – Molded and stamped components for laboratory instruments and diagnostic devices.

Sterilization & Storage Containers – Deep-drawn or compression-molded housings designed for medical-grade sterilization.

Artificial Limbs & Supports – Compression-molded or hydroformed structural components for prosthetics.

Orthopedic Bracing & Supports – Thermoformed or compression-molded devices for rehabilitation and patient support.

Assistive Mobility Components – Cold-formed and deep-drawn parts for wheelchairs, exoskeletons, and mobility aids.

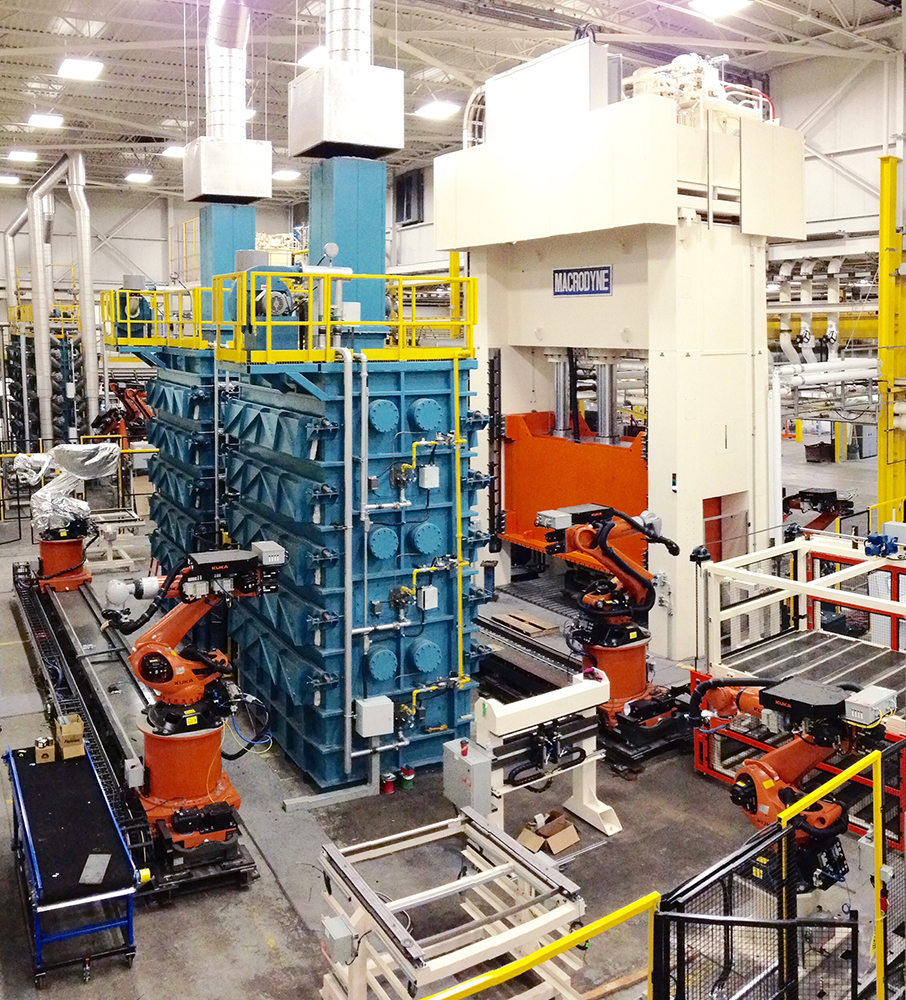

Macrodyne’s automation solutions go beyond basic robotics and conveyors, offering fully integrated, end-to-end systems designed for clean-room environments and high-precision production.

As a trusted partner to leading manufacturers, we deliver custom presses for medical manufacturing with advanced automation that enhances productivity, ensures process consistency, and minimizes downtime.

Let Macrodyne deliver the precision and performance your manufacturing demands with industry-leading hydraulic presses and servo presses.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.