Deep Drawing Presses

Industrial Deep Draw Metal Stamping Presses

Get flawless part quality, faster cycle times, less waste and more production flexibility.

Our deep draw presses deliver repeatable precision for a wide range of custom part sizes and geometries.

These deep drawing presses work with a variety of materials, including aluminum, low-carbon steel, stainless steel, copper, brass and more.

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Bed Size

Daylight

Stroke

Installed Power

Industrial Deep Draw Metal Stamping Presses

Get flawless part quality, faster cycle times, less waste and more production flexibility.

Our deep draw presses deliver repeatable precision for a wide range of custom part sizes and geometries.

These deep drawing presses work with a variety of materials, including aluminum, low-carbon steel, stainless steel, copper, brass and more.

View Past Projects

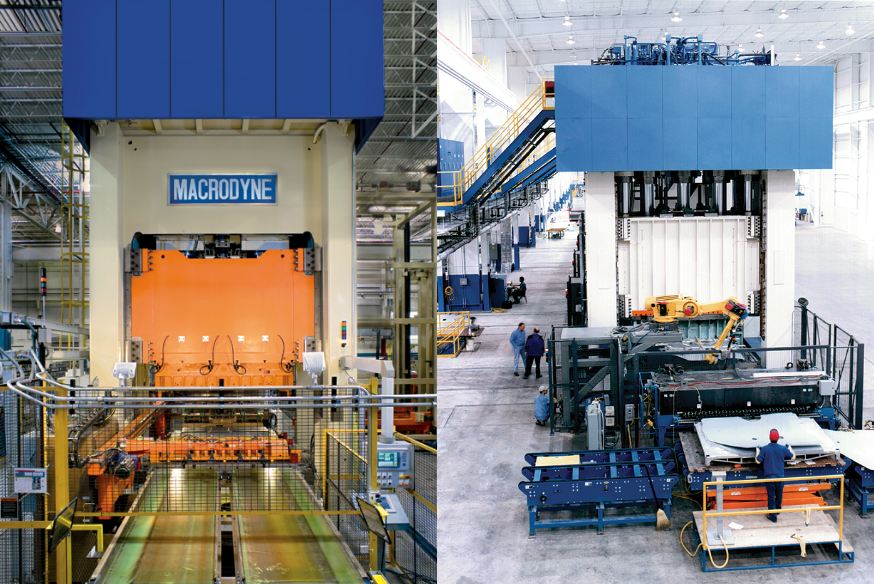

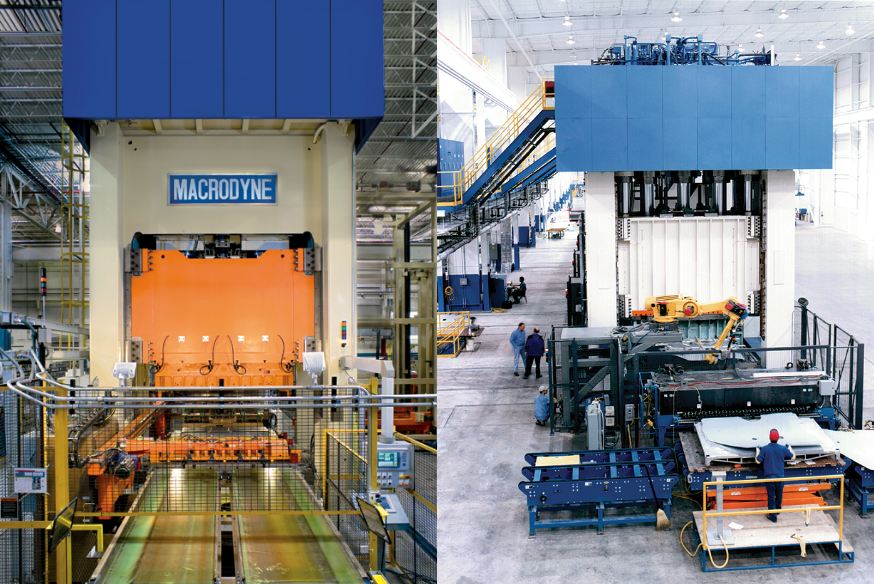

Superior Deep Drawing Manufacturing

Macrodyne’s custom hydraulic presses can be optimized for a wide variety of deep drawing manufacturing applications. Produce deep-drawn metal stamping components quickly and cost-effectively with utmost precision. Our deep drawing presses can be configured to produce parts for a variety of industries, including:

Automotive

Body Components, Oil Pans, Gas Tanks & More

Appliance

Washer/Dryer Panels, Fridge, Stove & More

General

Fan Hoods, Air Conditioner Panels, Sinks & Light Fixtures, Electrical Fixtures

Cookware

Pots, Pans & More

The Advantages of Using the Deep Drawing Process in Your Manufacturing Operations

The deep drawing process offers numerous advantages compared to traditional molding and casting processes. Each Macrodyne deep draw press is engineered for your unique application, giving you precise control over force distribution and material flow. The result: superior parts without wrinkling or tearing, plus reduced waste and lower production costs.

Custom Deep Drawing Presses

Macrodyne custom-builds deep drawing presses in a wide variety of configurations, including:

- Single-action

- Single-action with cushion

- Double-action

- Double-action - with cushion

- Triple-action

Enhance Your Deep Drawing Press

In addition to the configurations listed above, your deep drawing press can be outfitted with several custom options, including:

- Passive, active, and multi-point cushions – for precise material control during forming

- Multi-point blank holders – to secure blanks and prevent wrinkling

- Die clamping & lifting packages – to speed up tool changes and reduce downtime

- Parallel leveling packages – for consistent press alignment and part accuracy

- Stroke-limiting and shock-dampening packages – to protect equipment and extend press life.

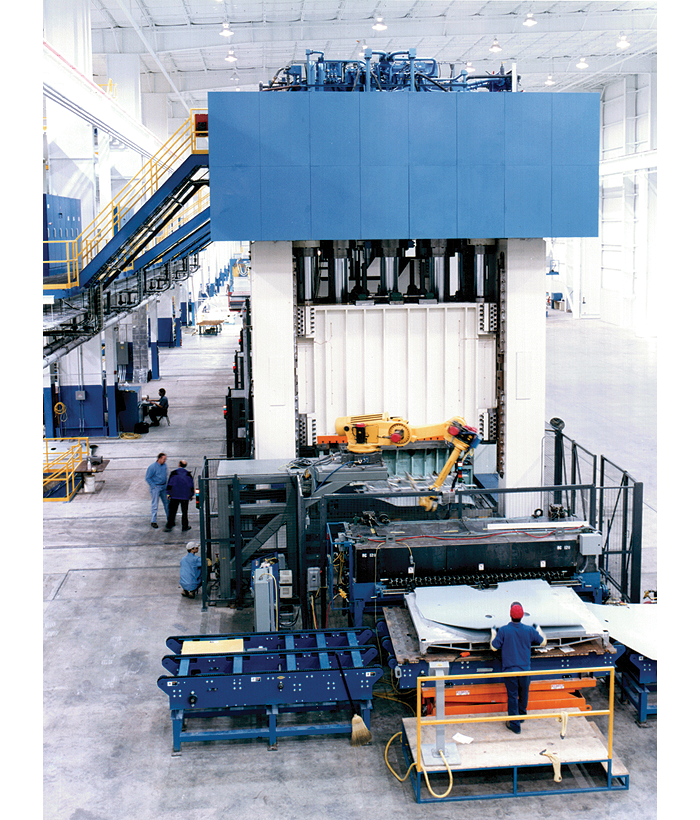

Automate Your Line with Macrodyne

Take your deep drawing manufacturing line to the next level with a variety of custom automation options. Speak with a Macrodyne press expert about our wide variety of automation solutions, including:

- Robots – automate part handling for speed and safety

- Coil feed systems – streamline continuous production

- Destackers – improve efficiency in sheet loading

- Transfer systems – move parts seamlessly between stations

- Scrap conveyors – remove waste to keep lines clear

- Automated die storage & retrieval systems – cut setup times