Minimize Idle Time. Maximize Productivity.

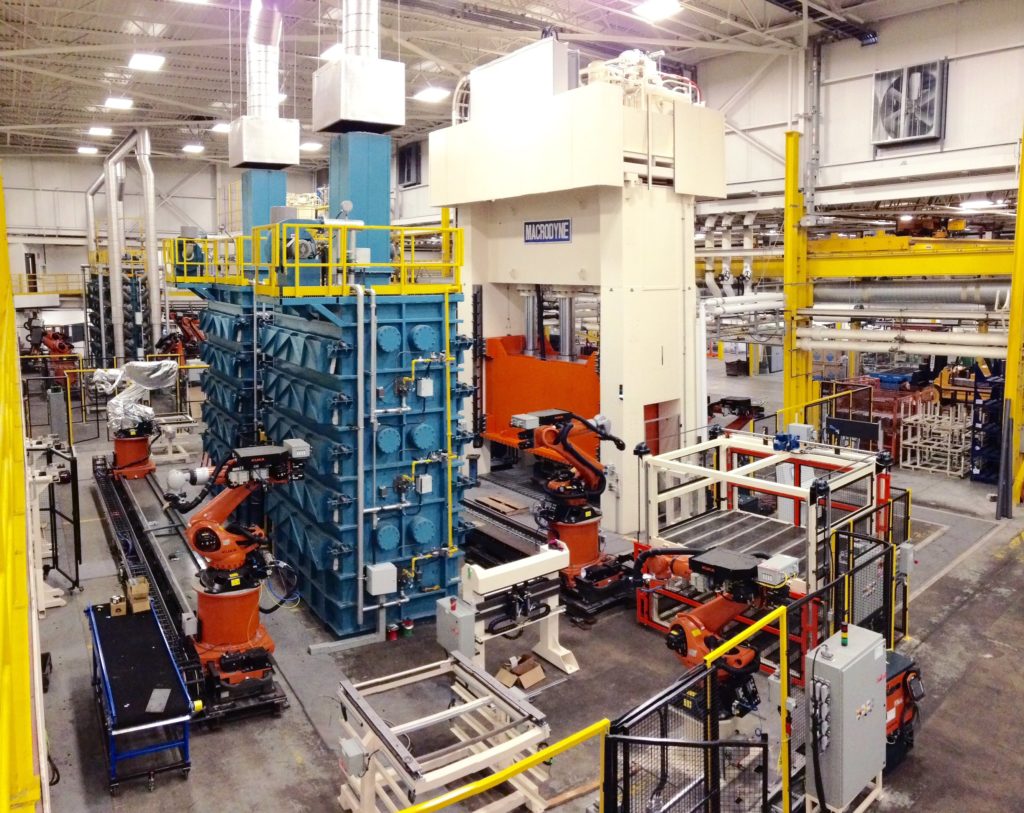

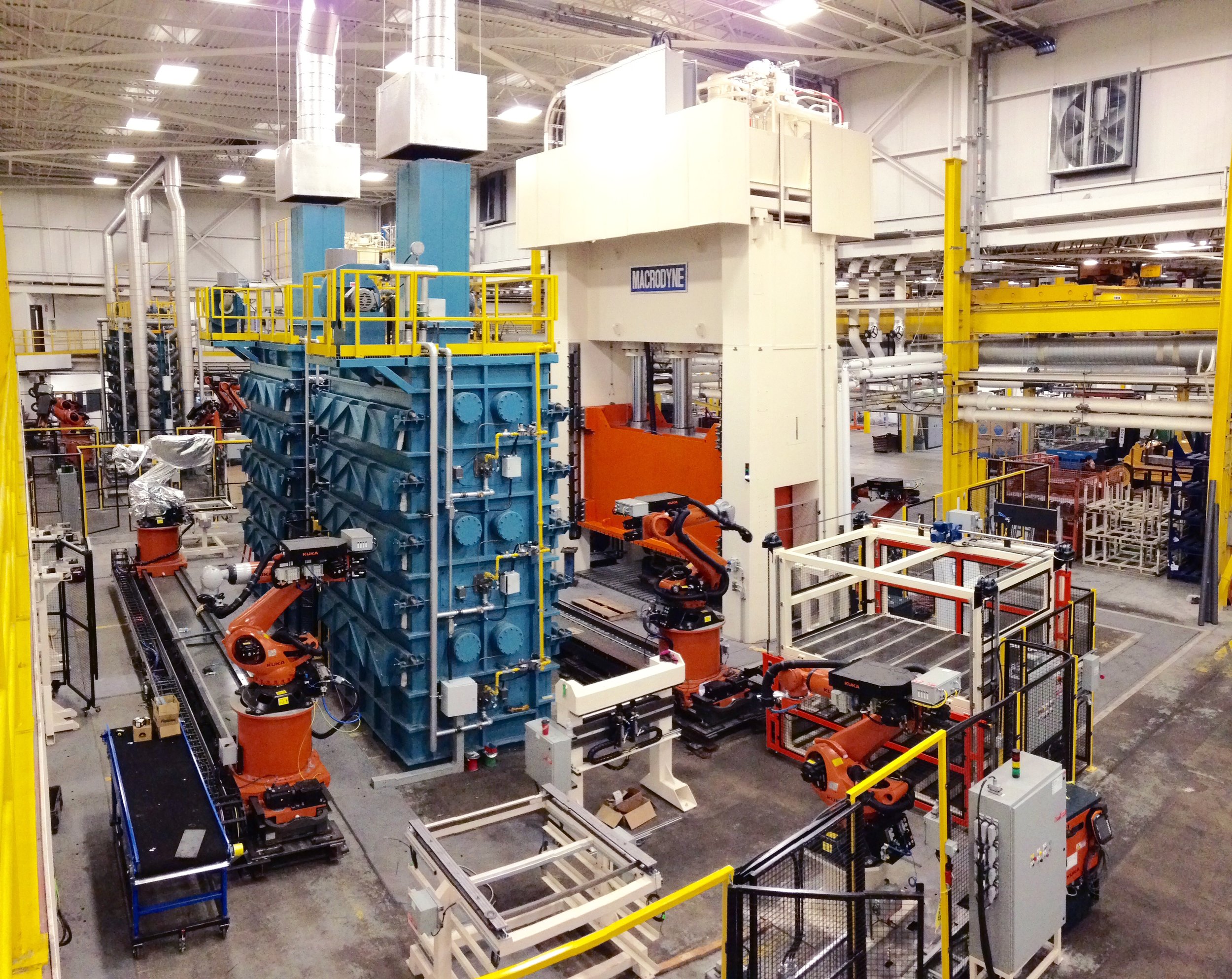

Our automation division is a world-class designer of advanced manufacturing machines, including specialized material handling systems. When required, we can design and build custom solutions to load/unload presses and move parts from station to station, particularly when nothing like it exists off the shelf.

We are dedicated to cost-effective solutions. When developing material handling systems, our intentions are never to reinvent the wheel. Instead, we work closely with industry-leading suppliers to integrate best-in-class material handling and press tending solutions for your application.

We can manage all the front-of-line automation, end-of-line automation, and everything in between. Find out how we can put our world-class experience to work for you.

Explore our range of material handling solutions. The systems below are just the start – ask us about our experience in developing custom automation solutions unique to your project

Improve your die management with storage racks, automated changing systems, and die lifters, enhancing operational efficiency and safety.

Achieve precise material feeding with roll feeders, servo feeders, and air feeders, enhancing the accuracy and consistency of your press operations.

Automate the loading of raw materials with AGVs, conveyor belts, and robotic loaders, boosting efficiency and reducing manual handling.

Effortlessly transport finished products away from the press with conveyors, robotic unloaders, and chutes, streamlining your production line.

Organize and store your finished products efficiently with palletizers, robotic stackers, and stacking cranes, simplifying transportation and storage.

Ensure reliable removal of finished parts with ejector pins, air blast systems, and robotic ejectors, maintaining a consistent production flow.

Sort products accurately with vision-based, weight-based, and magnetic sorters, optimizing your quality control and product handling.

Accurately position materials or parts with indexing tables, robotic positioners, and alignment systems, improving the precision of your press processes.

Manage workflow variations with intermediate storage, accumulation conveyors, and buffer stations, ensuring a continuous and balanced production line.

Move materials seamlessly between stations with linear and rotary transfer systems, and pick and place robots, ensuring a smooth and continuous workflow.

Your automation system starts with you – your needs, your budget and, just as importantly, your preferred vendors.

To bring your project to fruition, we collaborate with the world’s leading innovators to develop a solution unique to you. Simply choose the level of automation that suits you and we will collaborate with our international partner network to develop the ideal solution.

Find out how we can help you build a handling system that fits your unique requirements.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.

Macrodyne has designed and built many other presses not shown on the website.

80% of our presses are custom designed to meet the specific specification of each client.