Next-Generation Servo Press Technology

100% Force, 100% Precision, Zero Compromise

Proven Reliability Meets Today’s Toughest Standards

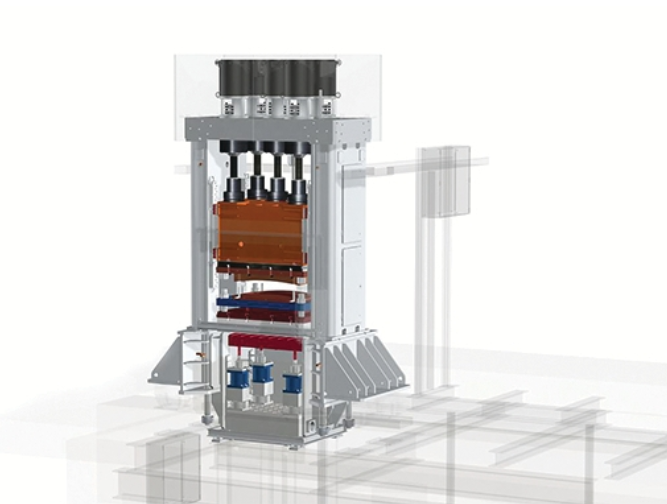

Decades ahead of its time with over 15 years of proven reliability in Europe, the German-engineered TRü Servo™ Technology is now available across most Macrodyne platforms.

This advanced direct-drive system delivers programmable tonnage and high-torque servo controlled motion for ultra-precise forming, all while reducing energy consumption with every cycle.

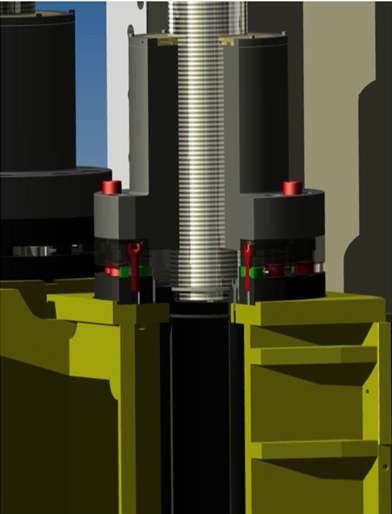

Unlike geared servo mechanical presses that rely on inefficient pendulum or rotary motion, TRü Servo™ Screw Press offers direct, linear control for faster, deeper and more flexible forming. The result? Motion profiles that aren’t just precise. They’re in a class of their own.

At the heart of this performance is our proprietary Deepest Draw™ software: the control system that enables complex drawing and forming profiles, real-time adaptability, and unmatched accuracy. It’s what makes TRü Servo™ the most versatile forming technology on the market.

Integrated into a wide range of Macrodyne platforms, TRü Servo™ Drives deliver adaptable, high-performance solutions for real manufacturing environments.

Extreme Precision, Productivity, and Reliability

The TRü Servo™ Press combines the full-force stroke capability of a hydraulic press — without cylinders or oil — with the unmatched control and precision of the most advanced servo systems on the market.

Customizable, it integrates seamlessly into any operation.

Key Benefits Include:

- Increased accuracy, flexibility and process speeds

- Clean-Room and Industry 4.0-Ready

- Smoother operation with minimal maintenance

- Versatility with servo-controlled motion options (digitally-controlled)

- Energy-efficient with reduced industrial noise

- Precision CNC system: faster than hydraulic, more accurate than servo-mechanical presses

Deepest Draw™ Technology

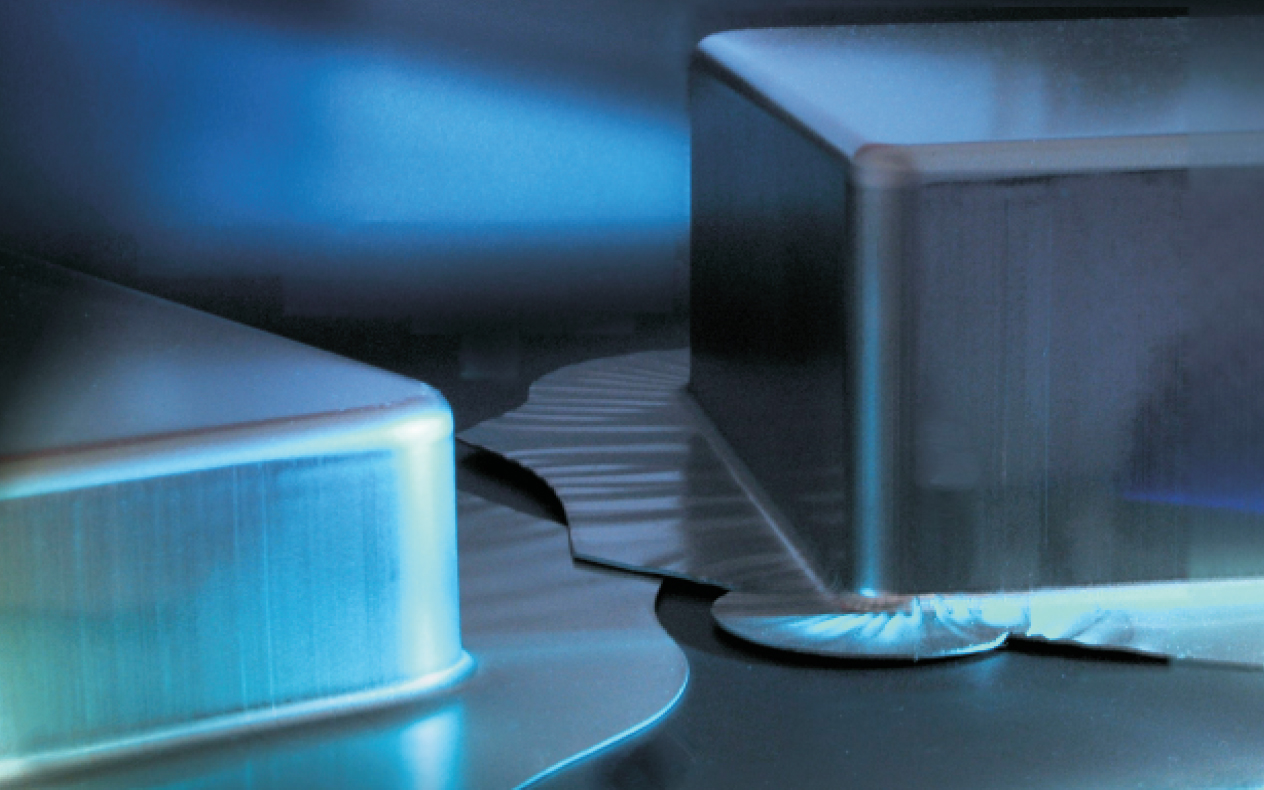

Up to 80% Deeper Draws – Something You Need to See to Believe

The Deepest Draw™ technology is upending how manufacturers think about the deep drawing process.

Using our TRü Servo™ system and proprietary Deepest Draw™ software, metals can be drawn up to 80% deeper than with traditional deep draw presses — servo mechanical or hydraulic. This technology greatly reduces wrinkling, and in some cases, prevents wrinkling altogether.

In addition, fewer process steps mean fewer tools, fewer operators, a smaller footprint, less handling and less energy, as well as reduced cycle time, all while increasing part quality and minimizing tooling complexity.

The TRü Servo™ Press Advantage

Designed for complex forming applications, the TRü Servo Press delivers unmatched precision, reliability, and part quality — even in the most demanding scenarios.

This system can greatly reduce and, in some cases, eliminate common defects like wrinkling and cracking, enabling cleaner geometries and consistent results across a range of materials and part shapes. Its advanced control capabilities open the door to entirely new forming strategies that traditional presses simply can’t support.

Backed by over 15 years of innovation, the Trü Servo Press isn’t just another servo solution. It’s a purpose-built platform that pushes beyond the limits of conventional forming, giving manufacturers the power to take on more challenging parts, reduce scrap and push every project over the finish line flawlessly.

Conventional Hydraulic Drawing Presses Vs. TRü Servo Deepest Draw Technology

Versatile Across Industries

Unmatched Versatility for Precision Manufacturing

- Deep Drawing

- Compression Molding

- Stamping and blanking

- Research presses

- Extrusion

- Metal forming

- Cold forging

- Stretch forming

- Die spotting

- Superplastic forming

- Many others

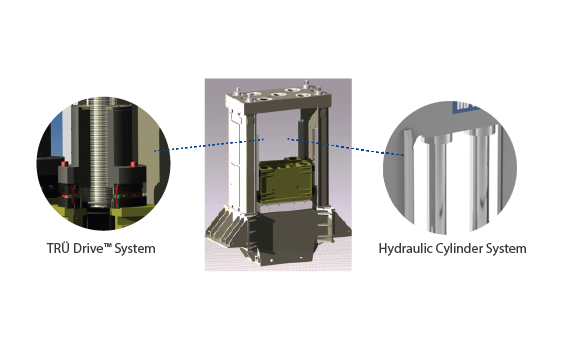

Any Standard Press Frame Can Have a TRü Drive™ System or Traditional Hydraulic Cylinder System